ENGINEERING & DESIGN

Rubber Consultants, the leading experts in engineering and design of elastomeric components.

Our team of world-renowned engineers specialises in developing a wide range of engineering solutions, from small automotive mounts and bushes to large marine fenders and anti-seismic devices.

Engineering Expertise: Our engineers possess extensive knowledge in elastomeric engineering components, as well as general engineering functions like shock, noise, and vibration control.

We cover various key areas:

- Material models for rubber

- Fatigue and strength analysis

- Crack growth assessment

- Noise and vibration control

- Creep and stress relaxation

- Friction and abrasion characteristics

- Design of rubber products such as seals and marine fenders.

Advanced Design Tools: To ensure precision and efficiency in our engineering projects, we employ cutting-edge design tools such as Finite Element Analysis (Marc), CAD software, and mathematical modelling. These tools enable us to deliver optimal solutions for our clients' specific requirements.

Manufacturing Support: Rubber Consultants also offers comprehensive manufacturing assistance, including mould design, cure cycle simulation, rubber to metal bonding, small-scale manufacturing, and prototyping services. Additionally, we specialise in creating custom rubber compounds tailored for engineering applications.

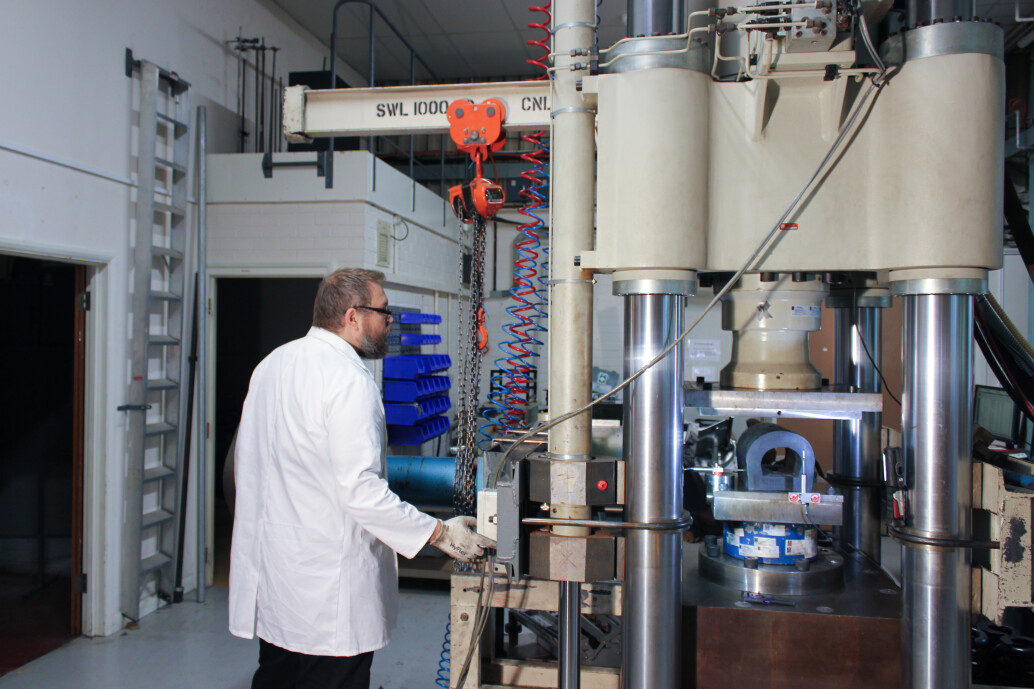

Bespoke Component Testing: Our well-equipped testing facilities accommodate a wide range of elastomeric components. With loads up to 2.5 MN, frequencies up to 1 kHz, and displacements from 0.1 μm p-p onwards, we can perform thorough and accurate testing to ensure the reliability and performance of your products.

Versatility in Testing: We conduct tri-axial testing of elastomeric components and utilise environment chambers for temperature and ozone testing. Our purpose-built fatigue test machines, friction testing capabilities, and rubber characterisation tests further enhance the versatility of our testing procedures.

Video Acquisition: For detailed analysis and documentation, we employ advanced video acquisition tools such as high-speed cameras, IR cameras, Digital Imaging Correlation (DIC), and optical microscopy.

Expert Consultation: As industry leaders, we provide expert witness services for legal disputes and have an extensive repository of research papers and technical publications. Our "Engineering Design with Rubber" technical bulletin serves as a valuable resource for engineering professionals.

Tailor-Made Training: Rubber Consultants offers tailor-made training courses covering all aspects of Engineering with Rubber, empowering professionals to enhance their knowledge and skills.

Development of Anti-Seismic Devices: Our expertise extends to the development of anti-seismic devices, including elastomeric seismic and vibration isolators, CE marking of laminated elastomeric structural bearings, viscoelastic dampers for seismic protection, rolling ball seismic isolators, and elastomeric wall joints for seismic protection of masonry infill.

Contract Research: We engage in contract research projects focused on Rubber-in-Engineering applications, partnering with industries to innovate and create advanced engineering solutions.

At Rubber Consultants, we take pride in our commitment to excellence, innovation, and customer satisfaction. Let us help you engineer the future with rubber.

Contact us today to discuss your engineering and design needs!