PRODUCT & MATERIAL TESTING

At Rubber Consultants, we provide a comprehensive range of mechanical testing services in compliance with various International, European, and National Rubber Standards.

Our testing facilities are equipped to evaluate the physical properties of rubber and elastomeric materials, allowing us to predict their performance in real-world product applications.

Customised Test Methods: In cases where standard test methods or specifications are unavailable, our experienced team can advise and assist in the development of appropriate test methods tailored to your specific needs.

Specialised Latex Product Testing: We offer specialised testing services for latex products, catering to various applications. Our testing capabilities include using a large-frame extensometer to pull latex samples to their maximum extensions, condom test machines for ISO 4074 compliance (both inflation and electrical leak testing), and equipment for testing latex gloves to EN 455 standard.

Test Facilities:

- Universal Testing Machines: Our advanced video extensometer-equipped systems precisely determine tensile properties such as tensile strength and elongation at break.

Additionally, we can program the equipment to perform complex cycles, assessing changes in rubber properties during initial deformation cycles in tension and compression. - Dynamic Mechanical Thermal Analysis (DMTA) Test Equipment: Configured to determine visco-elastic properties like modulus and damping (tan δ), our DMTA test equipment measures material responses to sinusoidal oscillatory deformation under controlled strain, temperature, and frequency conditions. It can analyse the temperature, strain, and frequency-dependent properties of sample materials.

- Hardness Test Equipment: We have various test equipment options for hardness measurement using the 'dead load' (IRHD) and Durometer (Shore A and D) methods.

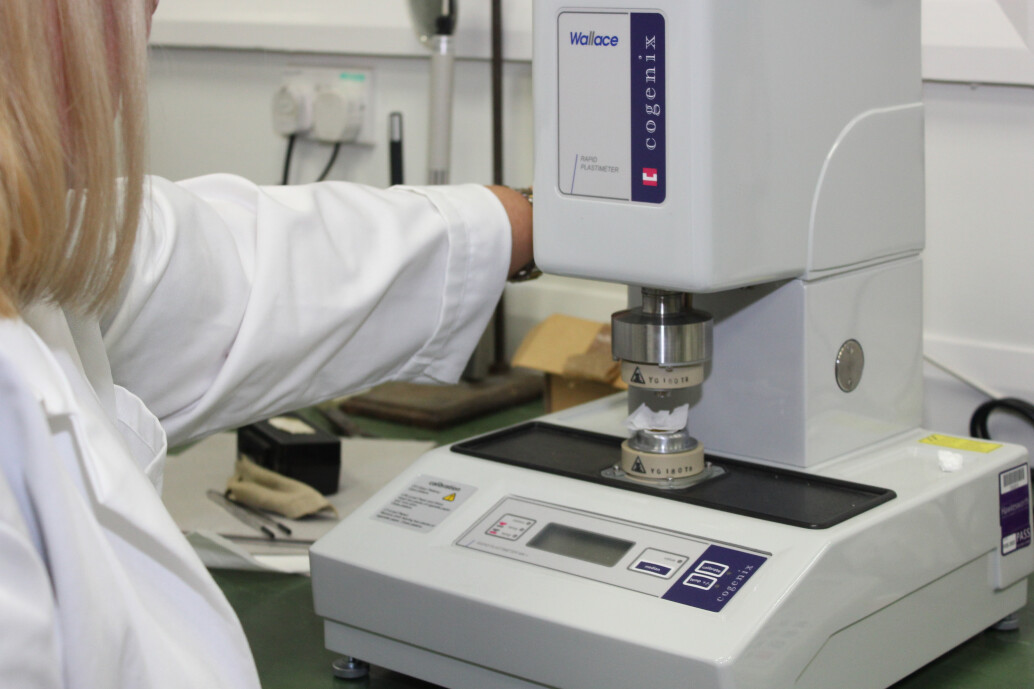

- Rapid Plastimeter: Equipment dedicated to measuring rapid plasticity and plasticity retention index of raw natural rubber.

- Resilience Test Equipment: Our equipment is configured for resilience measurement using the Dunlop tripsometer and Lupke pendulum methods.

- Abrasion Test Equipment: Configured for measuring abrasion properties via both DIN and Akron Methods.

- Fatigue Test Equipment: Test systems are available for measuring ring, tensile, or flex (De Mattia) fatigue.

- Ozone Test Chamber: This facility allows for determining ozone resistance under static strain conditions.

- Large-Frame Extensometer for Latex Samples: Specially designed for testing latex samples to their maximum extensions.

- Condom Test Machines: Including inflation tester and electrical leak tester for precise condom testing

Mechanical Test Equipment for Engineering Components: Our comprehensive set of mechanical test equipment caters to engineering components, capable of handling component tests (up to 2500kN dynamic) and material characterisation tests.

We also offer environmental chambers and an ozone room. Our specialist material test facilities cover thermal conductivity, friction over a wide range of normal stresses, crack-growth characteristics, and fatigue flaw size estimation.

We can provide expert advice on test selection, including characterising stress-strain behaviour for Finite Element Analysis simulation.

Tests for Rubbers and Elastomers: We perform tests for various properties of rubbers and elastomers, adhering to internationally recognized standards, including:

- Tensile properties (BS ISO 37)

- Hardness (BS ISO 48)

- Compression set (BS ISO 815-1)

- Tear resistance (BS ISO 34-1 Method A, B, C)

- Ozone resistance (BS ISO 1431-1, static)

- Heat resistance/accelerated aging (BS ISO 188).

At Rubber Consultants, we pride ourselves on delivering accurate and reliable test results, enabling you to make informed decisions about your products and materials.

Contact us today to discuss your testing requirements and how we can assist in ensuring the quality and performance of your rubber and elastomeric materials!